Hi! Paul here :)

This article is for anyone interested in learning a bit more about our journey - why we developed the PolYmers and how we did it. Come along and enjoy the ride!

Who we are and Why we do what we do

"La Paulade" began in 2017 as an engineering school R&D project. Back then, the goal was to design a narrow slalom truck for downhill longboarding competitions. My dream was to race on a product I've engineered and this was the perfect opportunity for me to do so. The first prototype - produced in 2018 - was a simply terrible. However by 2019, the design got pretty good, and I’m still riding it to this day.

Fast forward to the 2022 longboarding season. "La Familia" (one of the organisers of the French Championship) decided to test a new rule for their CDC Championship Race: limiting riders to a maximum of 3 sets of wheels in an effort to combat the post-Covid wheels price increase. The riders' feedback was great - racing became much cheaper, and the event was a success. But prices kept rising, and by 2023, finding 3 sets of race wheels at a fair price - and from a non-messed-up batch - became really challenging.

At the time, I had been working as a mechanical engineer for three years, designing products for various clients - often manufactured in China. This mix of product design experience and my background as a rider made me realise we needed something new: a European company working directly with manufacturers in China, enabling us to change the way we approach racing by giving control over wheel design, batch quality, and pricing.

In January 2024, I posted a draft idea on Facebook called "The La Paulade Race Project", which, to me, felt like the natural follow-up to La Familia’s new race regulations. The feedback from riders was overwhelmingly positive, something had to be done, and I needed a team.

Looking back, choosing the right teammates was the most impactful decision I made for La Paulade. They were stocked by the concept and joined right from the start. Since they were involved so early, they played a major role in the PolYmers' design. Every rider involved brought something unique to the table, contributing in ways only they could.

Looking back, choosing the right teammates was the most impactful decision I made for La Paulade. They were stocked by the concept and joined right from the start. Since they were involved so early, they played a major role in the PolYmers' design. Every rider involved brought something unique to the table, contributing in ways only they could.

The PolYmers' Secret

The PolYmers are intended as "easy race wheels" that embody the spirit of the La Paulade Race Project. This allowed me to define clear expectations for the wheels, ensuring they are suitable for fair and affordable racing.

- Fast enough - to keep racing entertaining

- Grippy enough - to enable the best rider to express his skills

- Smooth enough - to allow for intermediate riders to enjoy the feeling of riding freshies

- Affordable enough - to minimise the financial impact of the Race Project on an event organisation

The reason for that "enough" wording is that you don’t need the best wheel ever to organise fair racing. All criteria involve trade-offs - sometimes obvious ones, like grip / smoothness, and sometimes more complex ones, like top speed / consistency. Designing the "right" wheel is all about balancing these parameters to create something that meets your expectations.

The technical requirements of the wheel stem directly from those written-down expectations. I’m not going to dive into wheel theory here - as this will be discussed in another post later this year - but it involves taking all expectations and transforming them into quantified mechanical criteria.

- Fast enough -> large diameter (>75mm) + high-rebound urethane (>90%) + specific urethane chemistry

- Grippy enough -> large contact patch (>65mm) + specific lips profiles

- Smooth enough -> oversized core (<20mm radius urethane thickness) + lips profiles + urethane chemistry

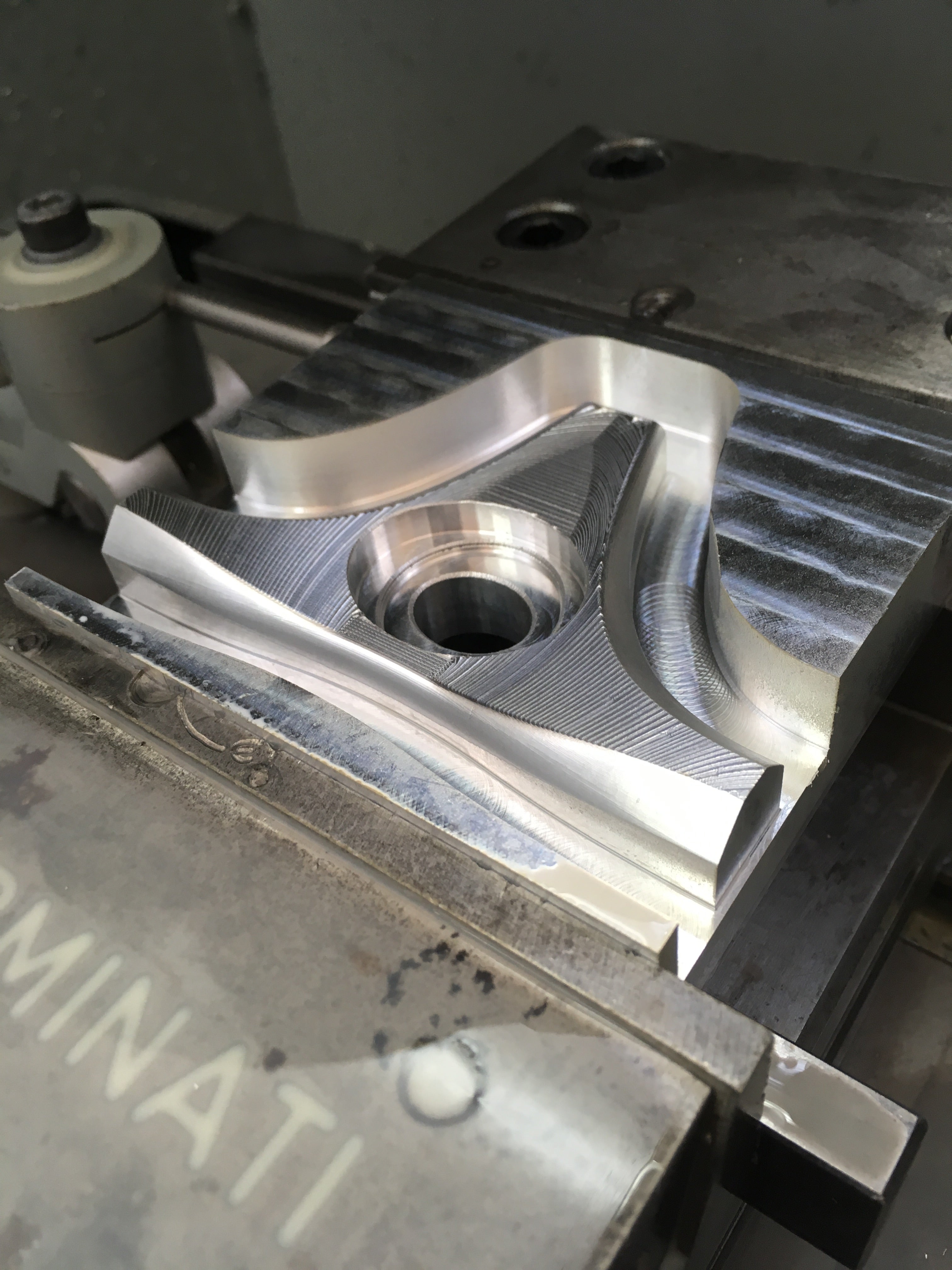

- Affordable enough -> manufacturing in China + leveraging non-exclusive moulds

These guidelines led to a 76mm wheel with a 65mm contact patch, featuring an oversized Kegel-like core and manufactured in China. Thanks to the specific urethane criteria, we were able to pinpoint the best available option within our budget, which we later double-checked by testing prototypes.

Once the mechanical part done, we moved on to setting up the look of the wheel. This was tricky for two reasons:

Firstly, the urethane's aspects (colour and texture) can impact its performance. Thanks to the chemical criteria we established for the urethane formulation, certain colours or textures were immediately ruled out. However, we had no way to precisely predict how our specific colour would perform.

Secondly, finding a unique colour combination in the current wheel market is incredibly challenging - unless you’re willing to copy an existing colour scheme or settle for something aesthetically unappealing... Powell has the flashy colours, Seismic the pastels, 88Wco their distinctive pink core... We needed to create a strong colour combination that would match our vibe. And so, Barth and Lucas came up with the idea of making it pink. Okay, but which pink now?!

And oh boy, were they right!

Remember when I told you we had no way to fully predict how the colouring would impact the urethane's performance? Well, call it beginner's luck, but making it pink was definitely the right call. For some mysterious chemical reason, our final pink prototypes were much smoother in slide than our previous white ones. The slides felt better, the hookups were crisper.. I couldn't pinpoint which chemical to thank, but who cares? We got lucky! And it's so effective that I wouldn’t be surprised to see more and more pink wheels popping up in the coming years to take advantage of that extra smoothness...

In the end, the secret of the PolYmers isn’t any one ingredient - not even its colour - but how they come together to create what we call “an easy race wheel", and the perfect tool to bring our Race Project concept to life.

Looking back, our 2024 launch was unbelievable. The support we received - from riders and industry professionals alike - was beyond anything we could have imagined. We met so many people who share our vision for growing this sport, and we’re determined to keep pushing forward.

Share:

How to skate safely on open roads: a European guide